A Year in Review: Highlights from 2025

2025 was a highly productive year for Hooper Quinn, and we are proud of the breadth and impact of the work we have delivered with our partners. As we look to 2026 with great excitement, we’d like to share some of our highlights and report on the achievements we’ve made in advanced engineering and new-technology ventures over the last 12 months.

We took on a huge diversity of projects in 2025, and in so doing succeeded in living out our core philosophy: to work on great projects with great people. Our engagements covered a wide range of technologies, sectors, and levels of maturity, from early-stage product development through to systems entering certification and production. Much of our output centred on taking partially formed ideas or existing programmes in need of high-impact support and carrying them forward into something concrete, more stable, better defined, and able to thrive under real operating conditions.

Here are a few examples of just some of the great things our team achieved in 2025.

Accelerating advanced engineering programmes in frontier R&D

Across the year, we worked with advanced technology companies who engaged Hooper Quinn to add depth, pace, and technical judgement to active engineering programmes. Our involvement typically focused on high-impact areas where additional expertise could accelerate progress, reduce uncertainty, and support confident decision-making without disrupting existing teams or delivery momentum.

In practice, this meant contributing directly to system architecture, detailed design, and hardware development within complex programmes, often where integration, manufacturability, and repeatability were critical to maintaining speed through later stages of development and into production.

Formula 1

We completed multiple mechanical design packages for our Formula 1 partners in their respective engine development programmes, work that is now progressing into production for the 2026 season.

Alongside this design work, our Chief Solutions Architect worked to stabilise and safeguard embedded software on a Formula 1 ECU programme, securing reliability, supportability, and long-term behaviour over short-term optimisation.

Marine

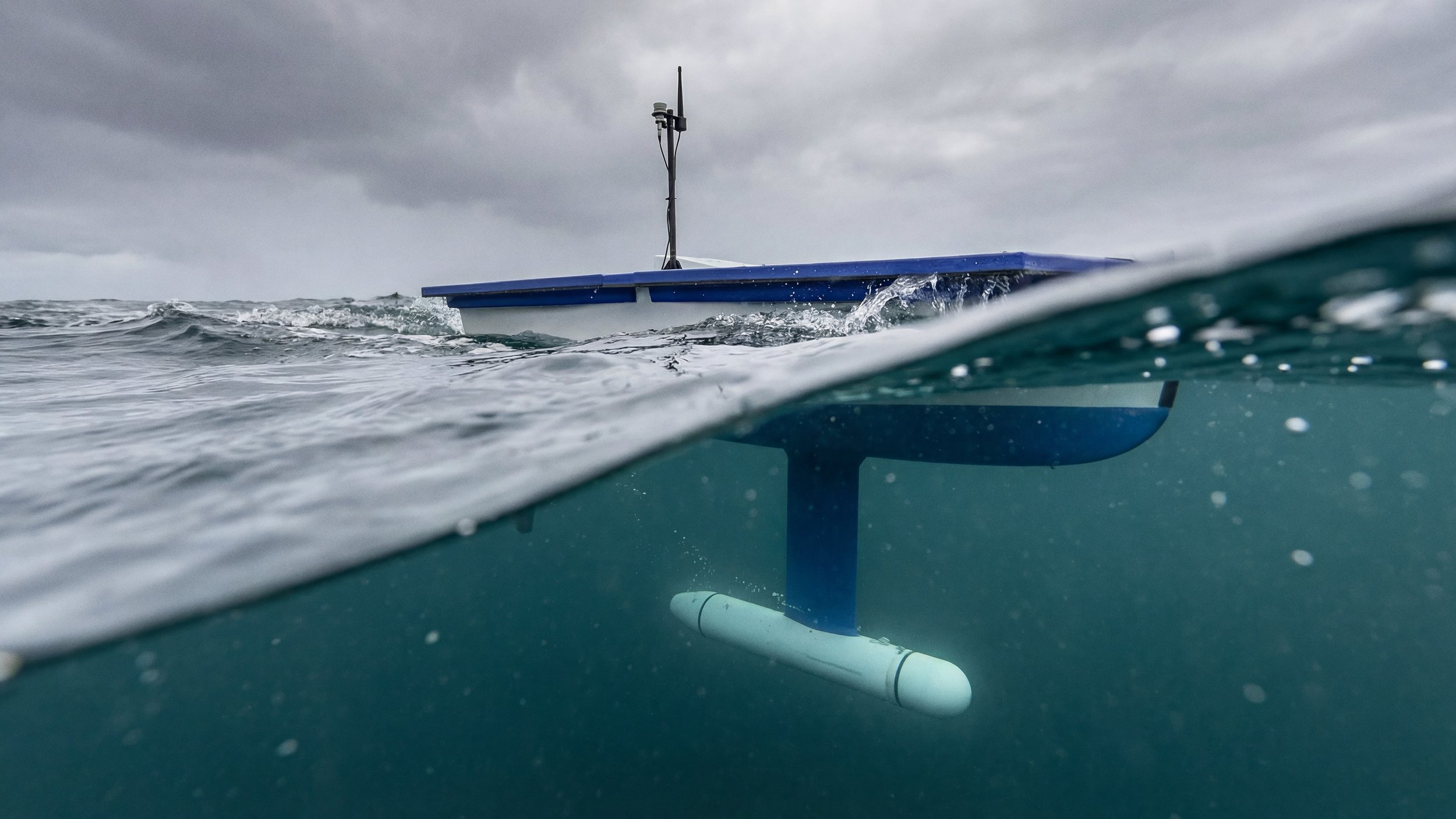

Shifting to quite a different environment, our team designed a compact rudder servo mechanism for an ocean drone micro-vessel platform, where packaging constraints, environmental exposure, and service access had to be resolved simultaneously.

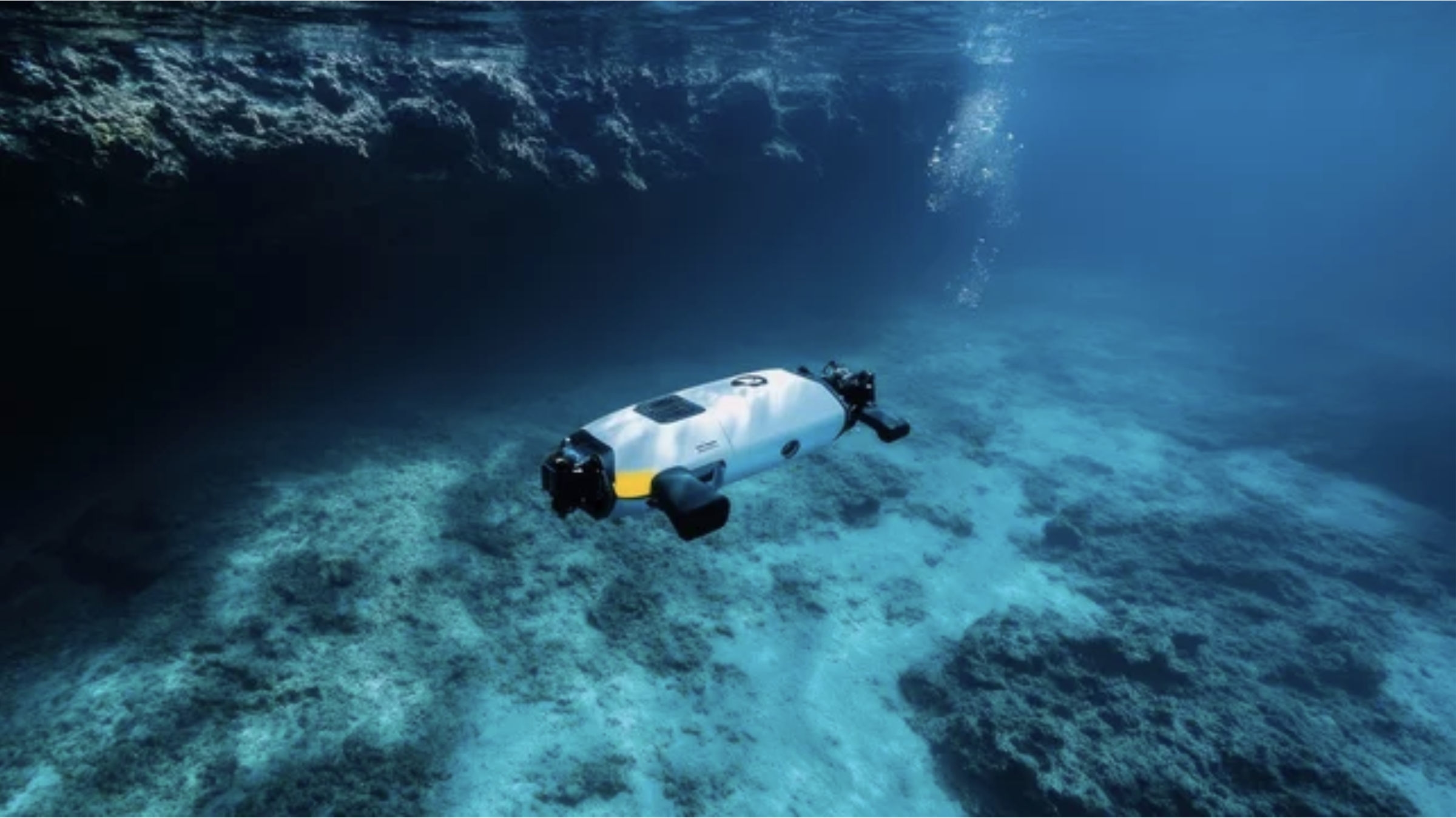

And beneath the waves, we also designed, built, and delivered five propulsion systems for use in unmanned research submarines, covering mechanical design, integration, and delivery for systems intended to operate without intervention.

Automotive

A unique and exciting opportunity arose as we carried out a discovery programme with a leading UK research institute assessing the recommissioning of a one-of-a-kind optical research engine, separating what remained technically viable from what could benefit from recent advances in engineering tools and approaches.

Simultaneously, our team designed, built, and delivered a full-scale 11 kWh battery mock-up for a leading UK advanced technology company, to support packaging studies, interface definition, and downstream decision-making.

We also delivered components and bespoke assembly tooling for a new micro gas turbine, utilising our expertise beyond design definition into build strategy and inspection, and produced wiring harnesses for a six-axis driving simulator, together with fixtures to support assembly and test.

Health and Performance

Some projects were shaped as much by their end users as by their technical requirements. One such project saw us design and deliver a specialist training-aid fixture for a hugely talented future Paralympian, where reliability, adjustability, and safe repeat use were central considerations.

We also supported Team Bath Heart, an inspirational engineering team from the University of Bath, with technical development input and commercialisation planning for a fully synthetic heart, contributing system-level engineering perspective within a tightly constrained regulatory environment.

Product development and incubation

Our product incubator activities are what mark Hooper Quinn off from other engineering firms, and with our support, 2025 saw the brith of several brand new UK companies, while programmes with existing partners were propelled to new levels of maturity, with several moving from development into delivery.

Chief among these, our team completed development testing for Off the Deck’s golf simulator, then established in-house production capability and delivered several production units.

Alongside this delivery work, we designed and implemented a feature-to-production product development operating system for Cura Terrae’s Centaur product, focusing on requirements traceability, configuration control, and decision ownership.

Further Highlights

Alongside delivery work, we continued to invest time in developing our capabilities and the next generation of engineers.

Student Incubator

In 2025, this included our first a student entrepreneur incubator programme, a platformed designed to give an HQ boost to promising early-stage technical ideas with impactful real-world applications. The programme supported the development of SureStride, a mobility-enhancing attachment for CAM boots invented by this year’s competition winner Oliver Chatting, intended to improve independence during lower-limb recovery. The work took the project from an initial prototype through design iteration, hands-on workshop development, testing, and early commercial structuring, including a dedicated commercialisation workshop delivered with our partners at LYVA Labs. By the end of the programme, the project had an improved, tested prototype, and a defined route forward.

Work Experience Placements

We also ran a work-experience placement, which saw the quite brilliant Amy Cowan join us for several stints across the year, integrating directly into live project teams. Amy’s placements were structured around practical contributions rather than observation, giving her exposure to real constraints, supervised responsibility, and the day-to-day realities of engineering work across design, build, and delivery.

Looking ahead

Taken together, the work delivered in 2025 is a good reflection both of the diversity and depth of problems our clients bring to us, and the manner in which we address them. Much of our impact will not be visible outside the programmes themselves, but all of it required careful technical judgement and disciplined execution.

As we move into 2026, a substantial programme of work is already underway. We remain grateful to the clients, collaborators, and suppliers who trusted us with complex and often time-critical engineering over the past year.